In the realm of automotive manufacturing, precision and efficiency are paramount. At the heart of many automotive components lies the intricate process of plastic injection molding. From interior trims to under-the-hood components, automotive plastic injection molding plays a pivotal role in shaping the vehicles we drive today.

In this comprehensive guide, we delve into the artistry and innovation behind automotive plastic injection molding, shedding light on its various facets and exploring how manufacturers leverage injection mould design to achieve exceptional results.

Understanding the Role of Plastic Injection Molding Manufacturers

Plastic injection molding manufacturers are the architects behind the scenes, orchestrating the intricate dance of design, material selection, and production processes. Their expertise extends beyond mere production; they are the stewards of quality, precision, and innovation in automotive manufacturing.

Innovations in Automotive Plastic Injection Molding

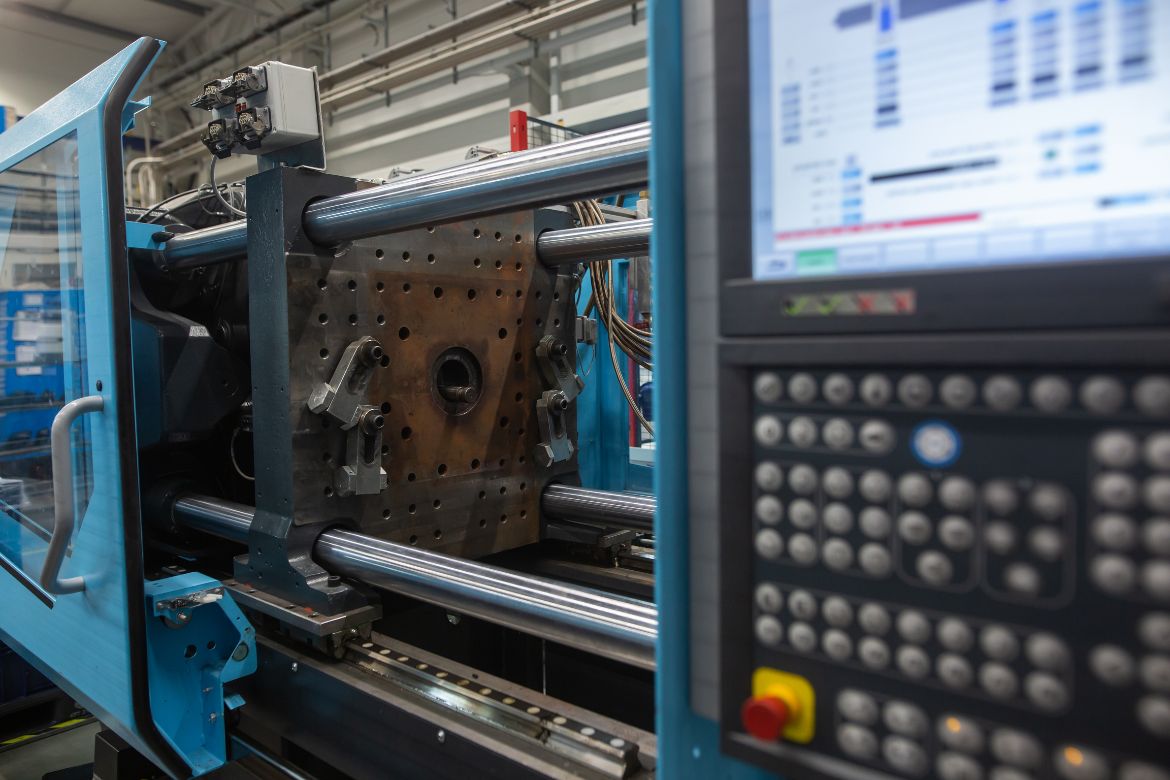

In recent years, automotive plastic injection molding has witnessed a surge in innovations. Manufacturers are embracing cutting-edge technologies such as computer-aided design (CAD), simulation software, and robotic automation to enhance efficiency, minimize defects, and accelerate production cycles. These advancements are revolutionizing the automotive industry, enabling the creation of lighter, stronger, and more cost-effective components.

The Importance of Injection Mould Design

Central to the success of automotive plastic injection molding is the meticulous design of injection moulds. These precision-engineered tools serve as the foundation for producing intricate automotive parts with unparalleled accuracy. Manufacturers employ advanced techniques such as mold flow analysis, conformal cooling, and multi-cavity molds to optimize design iterations and minimize cycle times, ultimately enhancing productivity and cost-effectiveness.

Driving Excellence Through Collaboration

Collaboration is key in the realm of automotive plastic injection molding. Manufacturers work closely with automotive engineers, designers, and OEMs to translate conceptual designs into manufacturable components. By fostering open communication and leveraging synergies between design and production teams, manufacturers ensure that every aspect of the injection molding process aligns with the automotive industry’s stringent standards for quality, performance, and reliability.

For more vist: https://www.djmolding.com/

Meeting the Challenges Ahead

While automotive plastic injection molding holds immense promise, it also presents its share of challenges. Manufacturers must navigate complexities such as material selection, part geometry optimization, and sustainability considerations to stay ahead in a rapidly evolving landscape. By embracing innovation, embracing sustainable practices, and continuously refining their processes, plastic injection molding manufacturer are poised to overcome these challenges and drive the automotive industry forward.

In conclusion, automotive plastic injection molding is as much an art as it is a science. From the meticulous design of injection moulds to the seamless integration of advanced technologies, manufacturers play a pivotal role in shaping the future of automotive manufacturing. By embracing innovation, collaboration, and continuous improvement, they uphold the legacy of excellence that defines the art of automotive plastic injection molding.