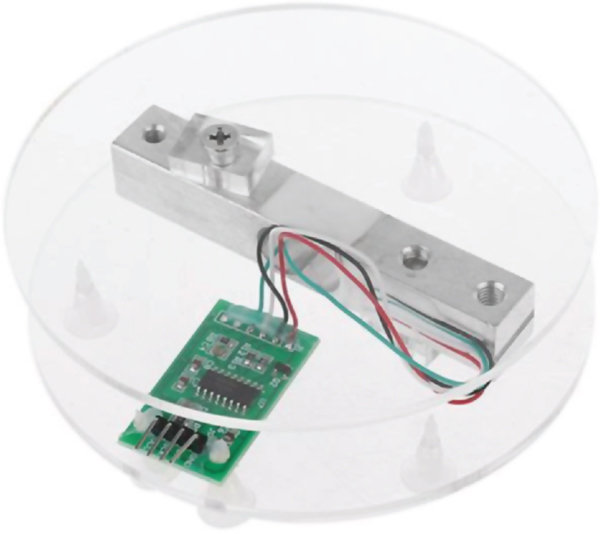

Mini force sensors are compact yet highly accurate devices designed to measure force, load, or pressure in small-scale applications. These sensors play a crucial role in industries such as robotics, medical devices, consumer electronics, and industrial automation, where precise force detection is required. Their small size allows seamless integration into complex systems without compromising performance.

Key Features of Mini Force Sensors

1. Compact & Lightweight Design

- Ideal for applications with limited space.

- Easily integrated into portable and wearable devices.

2. High Accuracy & Sensitivity

- Capable of measuring small forces with exceptional precision.

- Provides reliable data for quality control and safety applications.

3. Multiple Sensing Technologies

- Strain gauge-based sensors for durability and precision.

- Piezoelectric sensors for dynamic force measurements.

- Capacitive sensors for ultra-sensitive detection.

4. Versatile Mounting Options

- Available in button, beam, and diaphragm configurations for different applications.

5. Wide Measurement Range

- Suitable for detecting forces from a few millinewtons to several kilonewtons.

6. Digital & Wireless Options

- Integration with IoT and wireless communication for real-time data monitoring.

Applications of Mini Force Sensors in Various Industries

1. Medical & Healthcare

- Surgical robotics: Provides force feedback for precision control.

- Prosthetics: Enhances responsiveness and user comfort.

- Biomedical research: Measures small-scale biological forces.

2. Robotics & Automation

- Robotic grippers: Ensures secure handling of delicate objects.

- Collaborative robots (cobots): Enhances human-robot interaction with force detection.

3. Consumer Electronics

- Touch-sensitive devices: Detects pressure variations in smartphones and tablets.

- Gaming controllers: Enhances haptic feedback for immersive experiences.

4. Industrial Manufacturing & Quality Control

- Micro-assembly processes: Ensures proper force application in assembling small components.

- Product testing: Measures mechanical durability and stress resistance.

5. Aerospace & Automotive

- Structural testing: Evaluates material performance under different force conditions.

- Precision mechanics: Assists in fine-tuning components for optimal performance.

Choosing the Right Mini Force Sensor

When selecting a mini force sensor, consider:

- Measurement range: Ensure it matches the required force levels.

- Accuracy & resolution: Critical for applications demanding high precision.

- Size & form factor: Must fit within the device or system constraints.

- Output type: Choose between analog, digital, or wireless options for easy integration.

- Environmental durability: Assess resistance to temperature, humidity, and vibrations.

Conclusion

Mini force sensors offer an ideal solution for applications requiring compact, high-precision force measurement. As technology advances, these sensors are becoming increasingly sophisticated, integrating with smart devices, automation systems, and IoT platforms. Their versatility makes them indispensable in fields ranging from healthcare to industrial automation, ensuring efficiency, accuracy, and innovation in modern applications.